By: Denekew A. Jembere

Licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

Licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

Introduction

The Internet of Things (IoT), is enabling networked sensors and intelligent devices to be used in different business domains and environments, for collecting a high volume of data from heterogeneous devices and data sources in geographically disparate locations. The resulting high volume of data from these IoT sensors and devices are considered of high business value to drive artificial intelligence and predictive analytics. In this regard, data mining algorithms can be applied at different stages of the data, either to pre-process the data and reduce noise or to extract hidden patterns from the data in real-time.

Among the industries where the use of IoT devices making a huge impact with high-cost savings; improved production efficiencies; and, increased workplace safety for workers are manufacturing and the airline industry. In this regard, this article will outline the application of IoT in the airline industry at Rolls-Royce (n.d.); how the data collected from the IoT sensors used to improve products and services; the human, hardware, and software resource requirements of IoT-based solution. Finally, the article outlines a brief summary of the application of data mining theories and techniques, in IoT-based environments, using three different domains.

Rolls-Royce

Rolls-Royce Holdings plc (Rolls-Royce, n.d.) is a British multinational public limited company, based in London, and is incorporated in February 2011 owning the Rolls-Royce business established in 1904 (Wikipedia, n.d.-b). According to Wikipedia, Rolls-Royce is the second-largest aircraft engine maker; it designs, manufactures and distributes power systems for aviation and other industries; and, has major businesses in the marine propulsion and energy sectors. The history of the company, as detailed in Wikipedia (n.d.-b), Rolls-Royce has gone through creating several joint-ventures, re-incorporation, acquisitions and restructuring the business.

Among the joint ventures of Rolls-Royce was the Aero Engine Controls with a 50:50 ownership partnership with Goodrich (Wikipedia, n.d.-b). According to Wikipedia (n.d.-a), in December 2012, Rolls-Royce fully owned the Aero Engine Controls and, merged it with its own subsidiary: Optimized Systems and Solutions, forming the Rolls-Royce Control and Data Services. The Rolls-Royce Control and Data Services provide safety-critical controls and asset intelligence solutions for industrial power, marine, civil and military aerospace.

A. General Overview

A study by PwC (2014) reported that 71 percent of CEOs stating that they were developing future strategies or have concrete plans for making changes to their data management and data analytics. Moreover, a more recent study (PwC, 2017) reported that 73 percent of executives expect the Internet of Things (IoT) and artificial intelligence (AI) to bring about the biggest changes that future strategies or have concrete plans for making changes to their data management and data analytics. As a result, the use of IoT with highly scalable and sophisticated data analytics services built on the private or public cloud platform has become the focus of the airline and manufacturing industries.

B. Data and IoT in Rolls-Royce

As a data-driven company, with more than 30 years of data innovation (Rolls-Royce, n.d.), Rolls-Royce claims that it positioned itself to seize the technological advancements at the intersection of the Internet of Things (IoT) and Data Sciences, to help its customers navigate through the new big data landscape. Moreover, given its experience of using the power of data (Rolls-Royce, n.d.), Rolls-Royce details the readiness it has to partner with customers for enabling them to manage the vast quantities of information and reveal the meaningful insights that unlock the most value from their data.

According to Microsoft (2016), Rolls-Royce has more than 13,000 engines for commercial aircraft in service around the world and has been offering comprehensive engine maintenance services for more than 20 years, to improve aircrafts availability and efficiency. In relation to this, to cope with the increase in the volume and velocity of data, and to aggregate this data across its customers’ fleets, Rolls-Royce uses the Microsoft Azure IoT solution accelerators. According to Microsoft (2016), the integration with Microsoft Azure IoT solution accelerators enables Rolls-Royce to collect and aggregate data from disparate and geographically distributed sources at an unprecedented scale.

C. Data collection and the way it is used

According to Rolls-Royce (n.d.), the new IoT based solution offers the company a wealth of opportunity to the way they provide power to their customers with increasingly connected engines, which are contextually aware and comprehending. Among the data elements that Rolls-Royce collect and the ways it uses the information are:

Improve products and services

Rolls-Royce (n.d.) claims that its data-driven business experience coupled with the insights extracted from data for more than three decades has allowed the company to innovate and introduce the ground-breaking products and services. In this regard, Rolls-Royce is using data to bring together its products, services, and digital capability to realize the IntelligentEngine.

According to Rolls-Royce (n.d.), the IntelligentEngine is delivering reliability and efficiency for customers through the development of engines equipped with IoT sensors that are increasingly Connected, Contextually Aware, and Comprehending. The application of Artificial Intelligence (AI) on the data collected from these increasingly connected engines enables them to continually learn from each other and their broader operational environment, to become self-improving and reach new levels of performance.

Engine Health Management (EHM) data

The EHM data, collected from the aircraft engine and transferred to an operational center on the ground, is used to record and monitor the performance of an engine, helping to ensure its availability. As per Rolls-Royce (n.d.), with the help of thousands of IoT sensors on the aircraft engine, the latest EHM system is capable of measuring thousands of parameters and entirely new parts of the engine, unlike the earlier versions. As a result, Rolls-Royce claims that the new EHM service detects 97% of engine issues automatically.

Improved flight schedule and Maintenance Plan

As noted by Rolls-Royce (n.d.), flight delays and disruptions cost the airline industry millions of dollars every year. As a result of this, Rolls-Royce further explains, airlines are always looking for ways to improve the efficiency of maintenance activities for the smallest reduction in “aircraft on ground” (AOG) time can translate into a significant amount of money.

According to Microsoft (2016), data analysis in Rolls-Royce is performed on a rich set of data to create data models at scale and accurately detect operational anomalies to help customers plan relevant actions. In this regard, the Microsoft Cortana Intelligence Suite is helping to filter the signal from the noise across large data sets to enable Rolls-Royce to focus on finding the real value in the data (Microsoft, 2016). By using wider sets of operating data and using machine learning and analytics, Rolls-Royce spots subtle correlations to improve data models and provide insights for reducing service disruptions through improved flight schedule or maintenance plan.

Overall data usage, analytics and success stories

According to Roll-Royce (n.d.), enabled by the advancements in digital technologies and data analytics, Roll-Royce claims that it is gearing its entire business to better support customers in doing more with less. Using data collected from different sources and sensors, from the conception of products through manufacturing and deployment, Roll-Royce (n.d.) claims that new levels of performance have been demonstrated, as follows:

- Ability to analyze billions of data points per flight, by data experts.

- 10,000 times more data collection by current generations of aircraft than the 1990s or early 2000s era aircraft, with the next generation aircrafts increasing this by a new order of magnitude.

- £3.5Bn annual revenue boost by the pioneering industrial data services.

- Automatic detection of 97% of issues, by Equipment Health Management service

- 40% reduction in customer disruption, since 2005

- Ability to analyze 3 million flight sectors per year, by efficiency data experts.

- From 28% of airlines’ global routes, 100,000 tons of fuel-saving for our airline customers, which is enough fuel for a 747 to fly to the moon and back, 13 times

D. Snake-Robots – The future of Rolls-Royce IoT initiative

According to Rolls-Royce (n.d.), data collected from the increasingly connected engine, which is contextually aware and intelligent due to its thousands of sensors, is used to enable robotic technologies to improve the way engine maintenance is delivered. In this regard, Rolls-Royce is working on a project in partnership with the University of Nottingham and Metallisation for building ‘snake’ robots that are flexible enough to travel through an engine, like an endoscope, to speed up inspection by eliminating the need to take an engine off an aircraft.

E. Hardware, Software and Human resource needs

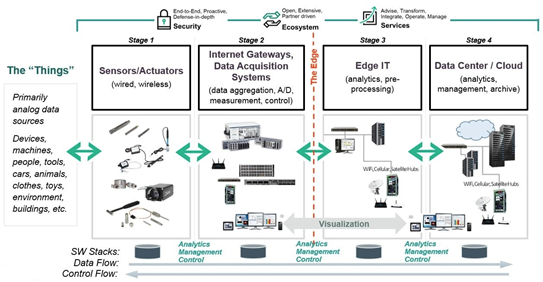

To enable the data collection, analysis and taking actions on the resulting insights, IoT based solution requires a clearly defined architecture that streamlines communication about the solution’s human resource, hardware and software components needs. In relation to this, using “The 4 stage of an IoT architecture” by Fuller (2016), which is depicted in Figure 1, would streamline such communication for system implementation and management.

Figure 1. The 4 Stage IoT Solution Architecture (Source: Fuller (2016))

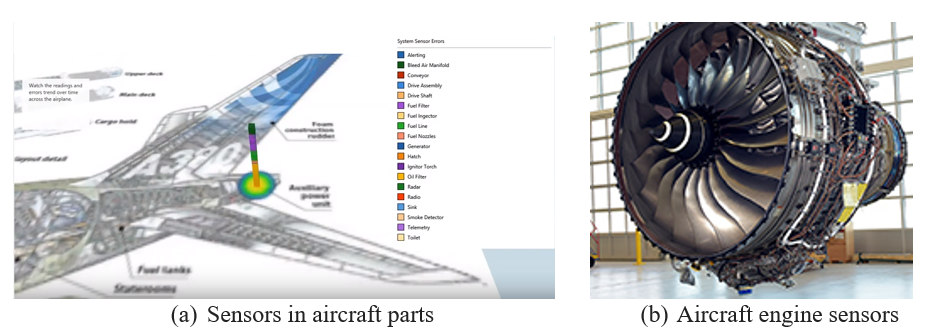

There are thousands of sensors that capture data from an aircraft (Smith, 2014), and more specifically the latest versions of aircraft engines are equipped with IoT devices and sensors that are used for two-way communications, to collect and transmit data as well as receive commands. The sensors on parts of an aircraft, and more specifically on the engine, that are used to collect and transfer data, can be depicted in Figure 2.

Since the specific implementation detail of Rolls-Royce’s IoT-based solution is private to the company and not publicly documented, for obvious reasons, the author assumes that the IoT solution architecture would be equivalent to the one depicted in Figure 1, taking the IoT sensors deployed on aircraft into account. As a result, based on the details from different sources (Fuller, 2016; Sob, 2017; Smith, 2014), below would be the likely human resource roles, hardware and software resources of Rolls-Royce IoT solution.

- Human Resources

- System Engineers – responsible for maintaining and replacing devices or sensors, with sufficient knowledge of the device types and their functions; alert types from the different types of devices and sensors, and actions.

- Software Engineers – responsible for implementing, testing and deploying features needed by the business, with sufficient knowledge of the different application platform interfaces (APIs) to integrate different IoT components.

- Software Systems Architect – responsible for leading the design and implementation efforts in the software stacks, software security and power aspects of the system.

- Solution Architect – responsible for exploring and determining the piece of hardware that would meet the business needs, with a high-level system architecture knowledge.

- Data Scientists – responsible for leading efforts to make value out of data by proactively fetching data from various sources, with sufficient understanding of both the business and the data sources to drive business solutions through choosing the right analytic algorithms and platforms.

- Data Analysts – responsible for proactively analyzing data to answer key questions from business decision-makers and stockholders, with sufficient knowledge to identify, analyze, and interpret trends or patterns in complex data sets.

- Hardware Resources

- Instrumentation Devices

- Sensors

- Actuators

- Current loop

- Highway Addressable Remote Transducer (HART)

- Controller devices

- Programmable logic controllers (PLCs)

- Remote Terminal Units (RTUs)

- Gateways

- Routers/gateways

- Aggregators

- Translators – From HART to Modbus TCP

- Communication Devices

- Wired: RS232, RS-485 serial communication; Ethernet; Highway; HART

- Wireless: PAN, LAN, WAN

- Personal Area Network (PAN): Bluetooth; RFID Tags and Readers;

- Local Area Network (LAN): Wi-Fi (IEEE 802.11)

- Wide Area Network (WAN): 3G, 4G, and 5G; Satellite (VSAT)

- Storage and Computing platform: Can be a local or on a cloud platform

- Edge computing or pre-processing computers

- Computers – for development and testing IoT implementations

- Data storage devices – for data storage and archiving

- Computing platform – for data processing and analytics

- Network load balancing hardware

- Software Resources

- Load balancing, Security and Access control

- Traffic load balancing and encryption – Layer 7 encrypted traffic

- Network access control – Which device (& policy) gets access to the network?

- Device control security platform – What’s the device doing?

- Application and Data security – Who can access which data through which application interface

- Data pipeline and analytics, and visualization

- Artificial Intelligence (AI) Model development software

- Big Data streaming, ingestion, transformation, compute and storage services

- Data visualization and alerting dashboard systems

IoT Data – Theories and techniques of Data Mining

The high volume of data generated by the Internet of Things (IoT) is considered of high business value, and data mining algorithms can be applied to IoT to extract hidden patterns from this data. The application of different data mining algorithms, either to pre-process the data to reduce noise or to extract hidden insight from the data in real-time, has become a mainstream application of data mining on IoT sensor-generated data. In this regard, the application of data mining, in IoT-based environments, is briefly summarized below using three different domains.

A. Predicting energy consumption and flexibility

To address a challenge in the identification and prediction of building energy consumption and flexibility, in the context of smart grids, Mocanu et al (2016) have proposed an approach that would use the latest smart meters to monitor the power consumption level of home appliances, in real-time. In addition to the Deep Learning (DL) data mining methods to build energy prediction, which their approach is inspired by, Mocanu et al developed a unified IoT based architectural framework for the different DL algorithms to perform energy disaggregation, flexibility identification and predictions, simultaneously. As a result, Mocanu et al claim that their novel approach, which is an IoT based framework to perform simultaneously and in real-time flexibility identification and prediction, performed well reaching a similar performance with the individual state-of-the-art models.

B. Measuring and monitoring water quality

Lowongtrakool and Lorwongtrakool (2018) used the IoT hybrid sensors, e-tongue and e-nose, for collecting data measurements of water chemical properties and different types of gases, respectively. Using different data mining algorithms, such as the Naive Bayes multinomial, Logistic and Simple Logistic classification algorithms, Lowongtrakool and Lorwongtrakool have concluded that hybrid sensors can be applied for the measurement and monitoring of water quality, at the inlet and outlet areas of water quality control plants.

C. Extracting meaningful insights and patterns in real-time

Considering the amount of data getting generated by heterogeneous devices implanted with IoT sensors and accumulated in storage servers over a period of time, Batra et al. (2018) have evaluated different data mining techniques to extract meaningful information in real-time. In this regard, the evaluation of Batra et al focused on the classification, clustering, and association-based data mining algorithms and their possible combinations. Based on the empirical analysis of their precision, accuracy, and recall, Batra et al concluded that the Frequent Pattern (FP) algorithm performed better than the other data mining algorithms. Batra et al further claim that their findings can be used to help choose the correct data mining technique with a particular application of IoT.

References

Batra, I., Verma, S., Verma, K. (2018). Performance Analysis of Data Mining Techniques in IoT. 4th International Conference on Computing Sciences (ICCS), 194

Bolton, D. (2017, May 02). Applause. Retrieved from The inflection point for consumer IoT adoption has come: https://www.applause.com/blog/smart-devices-internet-of-things/

Fuller, J. (2016, May 26). The 4 stages of an IoT architecture. Retrieved from TechBeacon: https://techbeacon.com/enterprise-it/4-stages-iot-architecture

HPE. (2017, Jun 21). Powering the Intelligent Edge: HPE’s Strategy and Direction for IoT & Big Data. Retrieved from SlideShare: Powering the Intelligent Edge: HPE’s Strategy and Direction for IoT & Big Data

Lowongtrakool, C., Lorwongtrakool, P. (2018). IoT Based Water Quality Measurement Using Hybrid Sensors and Data Mining. International Conference on Information Technology (InCIT), 1.

Microsoft. (2016, August 10). Rolls-Royce and Microsoft collaborate to create new digital capabilities. Retrieved from Microsoft – Customer Stories: https://customers.microsoft.com/en-us/story/rollsroycestory

Mocanu, D.C., Mocanu, E., Nguyen, P.H., Gibescu, M., Liotta, A. (2016). Big IoT data mining for real-time energy disaggregation in buildings. IEEE International Conference on Systems, Man, and Cybernetics (SMC).

PwC. (2014). Strategic sights set on transformation and innovation. Retrieved from PwC – PwC Global Airline CEO Survey 2014: https://www.pwc.com/gx/en/transportation-logistics/pdf/pwc-global-airline-ceo-survey-2014.pdf

PwC. ( 2016). Connected manufacturing: Collaboration realized. Retrieved from PwC Digital Services: https://digital.pwc.com/content/dam/pwc-digital/US/FeaturedVideos/Abstracts/VID_IP_Abstract.pdf

PwC. (2017). A decade of digital: Keeping pace with transformation. Retrieved from 2017 Global Digital IQ® Survey: 10th anniversary editi: https://www.pwc.ru/ru/publications/global-digital-iq-survey-eng.pdf

Rolls-Royce. (n.d.). Electrifying the future. Retrieved from Rolls-Royce: https://www.rolls-royce.com/innovation.aspx

Smith, M. (2014, November 13). IoT Plane Sensor Analysis. Retrieved from YouTube: https://www.youtube.com/watch?v=H43wNzv7to8

Sob. (2017, July 9). Drawing parallels between building an IoT system and building a PC. Retrieved from StackExchange: Internet of Things Beta: https://iot.stackexchange.com/questions/1775/drawing-parallels-between-building-an-iot-system-and-building-a-pc

Transcendent. (2018, October 16). How Connected Devices are Changing the Manufacturing Industry. Retrieved from IoTforAll: https://www.iotforall.com/iiot-devices-change-manufacturing-industry/

Wikipedia. (n.d.-a). Aero Engine Controls. Retrieved from Wikipedia: https://en.wikipedia.org/wiki/Aero_Engine_Controls Wikipedia. (n.d.-b). Rolls-Royce Holdings. Retrieved from Wikipedia: https://en.wikipedia.org/wiki/Rolls-Royce_Holdings

I glanced through this site and there’s so much helpful information, bookmarked 🙂

compare and contrast essay topics

Thank for your comment. Glad that you found helpful resources, in the site. More will come :).